From the Industrial Revolution to World War II tanks! Let's learn about the history of this diesel engine

Now the trucks around us are basically diesel engines. The improvement of diesel engine technology has also indirectly promoted the development of the commercial vehicle industry. Especially in recent years, the horsepower of domestic large-scale trucks and the domestic six technologies have promoted the upgrade and evolution of diesel engines.

Not only the wheels of trucks, but small diesel engines are also widely used in cars in Europe and other places. What is the incredible charm of diesel engines? What are the unique capabilities of diesel engines? Please investigate the history of diesel engines with the essayist.

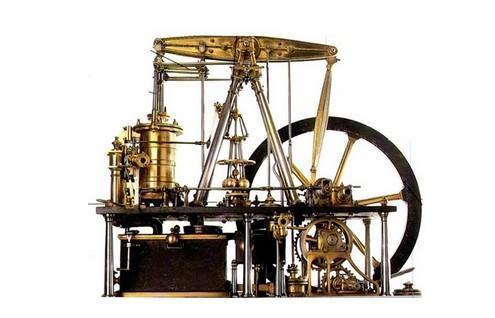

Past life: the core of the industrial revolution

Regarding the history of the diesel engine, it must first be traced back to his ancestor, the steam engine.

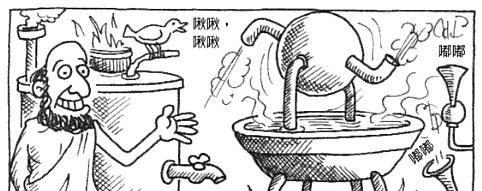

The earliest steam engine in the world is the steam rotating ball, invented by the ancient Greek mathematician Hiro. It mainly uses reaction force to make water vapor rotate. However, this kind of thing is lively for three-year-old children and is the first industry. The steam engine widely used in the revolution was produced by the French physicist Papin in the 17th century, invented the rod-type safety valve for the pressure cooker. In 1690, the prototype of the piston steam engine was developed.

When the piston steam engine is in operation, the water vapor made from the vaporized steam is first put into the piston. When the piston is pushed by the top dead center, the steam suction valve is closed and the cooling water valve is opened, so that the steam in the piston is liquefied and formed in the piston. In the vacuum state, the outside of the piston is affected by the atmospheric pressure to push the piston, so that it circulates. This steam engine is the earliest water extraction work used in the mining industry.

Later, the British inventor James Watt changed the piston steam engine from vertical to horizontal, changed the lever motion to rotary motion, and used the steam expansion pressure method to promote the piston motion. The steam engine was repeatedly improved in the first industrial revolution. However, the thermal efficiency is very low, and the defects such as large size and heavy structure can only be used for the power source of factories, ships, trains and other medium and large transportation vehicles.

The birth of the gasoline engine

With the vigorous development of the petroleum industry in the second half of the 19th century, a new type of power mechanical internal combustion engine was born.

In 1860, the Belgian French inventor Aston Noir invented the first gas-fired internal combustion engine. The exhaust port of this internal combustion engine is closed when the piston stops from top to bottom. The fuel and air are mixed at the front end of the cylinder while being compressed at the bottom. The volume of the crankcase increases, and the mixed gas is sucked into the space at the bottom. When the piston moves to the top dead center, the electric spark plug will ignite the mixed gas and promote the vibration of the piston.

At this time, the exhaust port is opened, the burned exhaust gas is discharged out of the piston, the suction port is opened, the mixed gas is sucked in, compressed into the combustion chamber on the upper part of the crankshaft, and the next action is started.

The gas internal combustion engine invented by Astro Boy has a simple structure and small volume, but when the gas enters the internal combustion chamber, some unburned mixed gas is discharged from the combustion chamber through the exhaust port. When the gas is burned, the stroke of pushing the piston down is short, so the fuel utilization efficiency is low. Therefore, it is used as a small vehicle and a small power source, which is the prototype of a two-stroke gasoline engine.

In 1876, the German inventor August August invented a new four-stroke internal combustion engine using a unique "automatic cycle" combustion technology in order to improve fuel utilization.

First, the piston stops moving below and sucks in the mixed gas. Then, the piston compresses the gas upward through the inertia of the crankshaft. After that, the electric spark plug ignites the mixed gas again, stops the piston underneath to move through the explosion, and finally opens the exhaust valve. The piston runs from bottom to top, and uses this inertia to remove exhaust gas to complete a working cycle. Compared with previous internal combustion engines, internal combustion engines with "double-ring" combustion technology can improve fuel efficiency.

Invention: whimsical ideas

After the 4-stroke internal combustion engine was invented by the automatic car, the young German partner Rudolf Diesel decided to completely remove the ignition system on this basis, and the fuel injection was completed after compressed air. After that, due to the chemical nature of gasoline, this approach could not be adopted. Dior It was decided to use vegetable oil as fuel. This movement later became an example of the use of vegetable fuel in internal combustion engines.

After the failure of the vegetable oil experiment, we paid attention to the diesel of petrochemical products, which was not taken seriously at the time, and successfully developed and ignited the world’s first diesel engine, and applied for a patent. Unfortunately, the original diesel engine lacked reliability, so the diesel engine received a lot of attention. Blow.

Diesel was swept away by a huge wave on a tanker crossing the English Channel. He was 55 years old. The diesel engine is also called "DIESEL".

Battlefield T-34

In the Second World War, the T-34 tank developed by the former Soviet Union showed its talents on the battlefield and became a battlefield achievement, which is inseparable from the secrets of the V12 diesel engine on board.

The 60V 12-cylinder diesel engine mounted on the T-34 tank adopts a special structure. Two rows of cylinders are first connected to a joint and connected to the crank. The crankshaft is connected to other powertrain equipment while driving a cooling fan to ensure the engine The inertia of the cylinder runs stably.

When the diesel engine starts, the air valve is first opened. After the piston descends to inhale air, the upward compressed air of the piston causes the air pressure in the cylinder to reach a peak value. When the fuel injection port injects high-pressure atomized diesel into the cylinder and encounters high-temperature and high-pressure air, it burns instantly and promotes the piston. When descending, the exhaust port is opened at this time, the piston squeezes the burned exhaust gas upward, and the 12 cylinders are staggered for a certain period of time without interrupting the power output of the engine.

Due to its relatively viscous nature of diesel fuel and less volatile compared with gasoline, the T-34 model has an optional additional fuel tank, strong diesel engine power (the maximum power at the time was 500 horsepower and the maximum torque of 2652 Nm) and the characteristics of high fuel utilization. The diesel engine became famous in one fell swoop.

Since then, diesel engines have been widely used in various industries, creating unparalleled value.

Note: The article comes from the Internet, if there is any infringement, please contact me to delete it.